Debbie Dai

Suitable for underground drainage pipes or channels;

• The section of the repaired object can be special shapes such as circle, oval, egg, square, etc.;

•The inner diameter of the applicable circular pipe is usually DN150~1200mm, and the largest pipe diameter can be up to DN2000mm;

• The length of a single (usually) repair can reach 200m, and other lengths must be customized;

★Product Description★

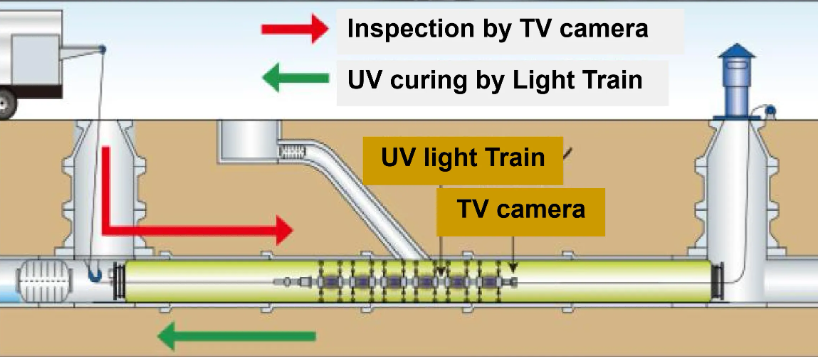

Penetrating installation - This reduces steps in the repair process. The liner is installed inside the existing pipe and inflated with compressed air. Using robotics, UV light is then used to cure and harden the lining to create the new pipe. Due to the lined design, no pre-lining or grouting is required to stop infiltration.

Small Footprint - The lightweight portable equipment used in the UV curing process makes it easy to access difficult areas, which is critical in tight and sensitive areas such as near lakes and backyards.

Environmentally Safe - The UV curing process does not use water, so you can leave your heavy water equipment at home. This results in a smaller footprint and less impact on resident property. Conventional steam and water treatment methods also generate gas, requiring protection for workers and residents. UV light avoids all of these situations.

Faster cure time - You can maintain about 5 feet of pipe per minute, although it depends on liner thickness. This significantly reduces the time needed to repair the pipeline, which means less service downtime for local residents.

No excavation at all - All access to pipes when using UV curing is through manholes and by robotics without excavation. Excavation can be an expensive and destructive process.

★Product Specifications★

|

Material |

PE/PA/PE |

|

Structure |

11 Layer Co-Extrusion |

|

Thickness |

200um,Support customer customization |

|

Length |

Up to 2150mm |

|

Color |

Normally Yellow, Support customer customization |

|

Certification |

ISO, SGS, FDA, ROHS, BPA free |

|

Feature |

Anti-UV, High Puncture Resistance, Low Oxygen Transmission Rate, Low Water Vapour Transmission Rate, |

★Applications★

• Suitable for underground drainage pipes or channels;

• The section of the repaired object can be special shapes such as circle, oval, egg, square, etc.;

•The inner diameter of the applicable circular pipe is usually DN150~1200mm, and the largest pipe diameter can be up to DN2000mm;

• The length of a single (usually) repair can reach 200m, and other lengths must be customized;

★FAQ★

Q1. Are you a factury or trade company?

A1. We are professional maker of multi-layer coextrusion barrier composite film, which has over thirty years' experience in this field.

Q2. what's your product equipment?

A2. 11 layer WH blown film line from German,

9 layer Macchi blown film line from Italy,

9 layer BE blown film line from Canada,

7 layer Macchi blown film line from Italy,

Q3.Can you provide sample?

A3. Yes, the sample is free, we will be very grateful if you can pay shipping cost.

Q4. How do you test your product?

A4.Our company has a dedicated laboratory, we will have a professional product testing, we can provide technical data sheet for each product

Q5. What should be provided when placing orders?

A5.The material, structure, size, thickness, width, length, and order quantity

★Contact Us★

Debbie, Dai (International Trade Manager)

Mobile:0086-18715575829 Email: debbie@hc-business.com

WeChat:008618715575829 WhatsApp:0085252745717