Debbie Dai

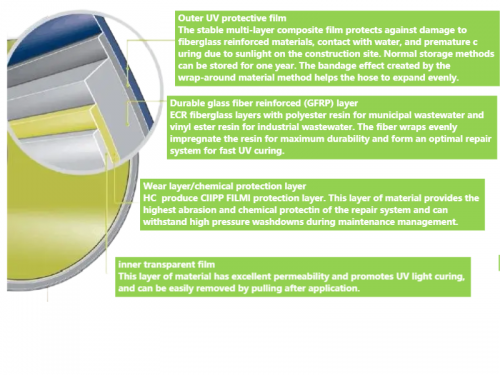

Anti-UV,

High Puncture Resistance,

Low Oxygen Transmission Rate,

Low Water Vapour Transmission Rate,

★Product Description★

CIPP inversion method hot water curing repair technology:

The inversion method uses air or water to deliver resin-coated hoses into underground pipes by inversion. This method allows for quick and easy feeding of materials. The hose is heat-hardened to form a high-strength lined new pipe within an existing pipe.

CIPP drag-in UV repair technology:

The UV light curing method uses the dragging method to drag the material hose into the underground pipeline. After hardening by UV-curing technology, a new lined pipe is formed in the existing pipe. This method requires a lot of pulling force when the material hose is pulled in, and generally pre-lays the mulch in the pipeline, and then implements the construction.

Construction process:

1. Pull in (before pulling in the lined hose) the protective film of the lined hose

2. Pull in the lined hose

3. Inflatable lined hose

4. CCTV monitoring of UV curing process of lined hose

★Product Specifications★

|

Material |

PE/PA/PE |

|

Structure |

11 Layer Co-Extrusion |

|

Thickness |

200um,Support customer customization |

|

Length |

Up to 2150mm |

|

Color |

Yellow, Transparent, Support customer customization |

|

Certification |

ISO, SGS, FDA, ROHS, BPA free |

|

Feature |

Anti-UV, High Puncture Resistance, Low Oxygen Transmission Rate, Low Water Vapour Transmission Rate, |

★Applications★

• Suitable for underground drainage pipes or channels;

• The section of the repaired object can be special shapes such as circle, oval, egg, square, etc.;

•The inner diameter of the applicable circular pipe is usually DN150~1200mm, and the largest pipe diameter can be up to DN2000mm;

• The length of a single (usually) repair can reach 200m, and other lengths must be customized;

★FAQ★

Q1. Are you a factury or trade company?

A1. We are professional manufacturer of multi-layer coextrusion high barrier composite film, which has over thirty years' experience in this field.

Q2. What are your main products?

A2.We are flexible packing supplier, like buffer cushion film, vacuum bags/ film, EVOH film, UV-CIPP film etc.

Q3.Can you provide sample?

A3. Yes, the sample is free, we will be very grateful if you can afford shipping cost.

Q4. How do you test your product?

A4.Our company has a dedicated laboratory, we will have a professional product testing, we can provide technical data sheet for each product

Q5. What should be provided when placing orders?

A5.The material, structure, size, thickness, width, length, and order quantity.

★Contact Us★

Debbie, Dai (International Trade Manager)

Mobile:0086-18715575829 Email: debbie@hc-business.com

WeChat:008618715575829 WhatsApp:0085252745717